Electrical Protective Equipment and Live-Line Tools

These items must be appropriately used and cared for to maintain their insulating capabilities.

This article will address two unique areas of electric power regulatory standards: electrical protective equipment and live-line tools. As with all articles in this series, let’s start with the hazard. Electric power workers have exposure to electric shock hazards with extremely high risk of serious injury or death. Although personal protective equipment should always be considered the last line of control, electrical protective equipment – when designed, manufactured, tested, maintained and used appropriately – provides a required control to prevent serious injuries.

Electrical Protective Equipment

In 2014, OSHA adopted a new construction standard on electrical protective equipment (29 CFR 1926.97) and revised the general industry standard (29 CFR 1910.137). Electrical protective equipment – referred to as “insulating equipment” within the OSHA standards – falls under OSHA’s PPE requirements, so it is important to remember that it must be included in the required written workplace hazard assessment certification, which identifies the workplace being evaluated, the person performing the evaluation and the date of the evaluation.

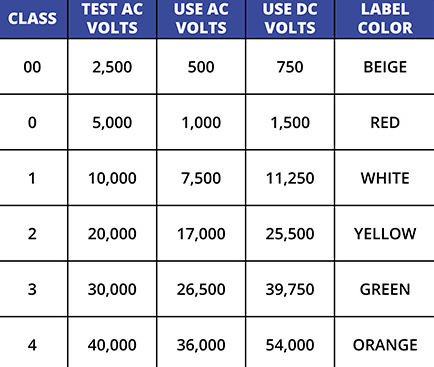

Covered electrical protective equipment includes rubber insulating blankets, matting, covers, line hose, gloves and sleeves. Each of these covered items must be clearly marked, identifying the class, which ranges from Class 00 to Class 4; the type, which includes Type 1, non-ozone resistant (natural rubber), and Type 2, ozone resistant; and the manufacturer’s identification. Electrical protective equipment that does not have clear visual markings must be immediately removed from service and disposed of properly.

Maximum Use and Testing Requirements

Electrical protective equipment must meet an electrical AC/proof test within the design voltage before use and as indicated within the standard. The AC/proof test must indicate that the equipment can withstand the voltage applied continuously within the established initial and retest times. Although equipment has a design voltage, it cannot be utilized over the maximum-use voltage, which must be used to establish the required PPE. The following chart shows the class, maximum-use voltage and AC/proof test details.

Testing Requirements

OSHA has test requirements for electrical protective equipment. It should be noted that these are the minimum requirements; many employers have much more detailed and rigorous standards. The minimum test requirements are:

- Rubber insulating line hose: Upon indication that the insulating value is suspect and after repair.

- Rubber insulating covers: Upon indication that insulating value is suspect and after repair.

- Rubber insulating blankets: Before first issue and every 12 months thereafter; upon indication that insulating value is suspect; and after repair.

- Rubber insulating gloves: Before first issue and every six months thereafter; upon indication that insulating value is suspect; after repair; and after use without protectors.

- Rubber insulating sleeves: Before first issue and every 12 months thereafter; upon indication that insulating value is suspect; and after repair.

Maintenance and Storage Requirements

OSHA states that electrical protective equipment must be maintained in a safe and reliable manner. It is important to utilize ASTM standards to determine industry best practices for the use and care of specific types of electrical protective equipment. A listing of consensus standards can be found in Appendix G to 1910.269 and 1926 Subpart V, “Reference Documents.”

Electrical protective equipment is required to be inspected for damage before each day’s use and immediately following any incident that could reasonably be suspected of causing damage. Defects include but are not limited to holes; tears; punctures or cuts; ozone cutting; an embedded foreign object; and any textural changes, such as swelling, softening, hardening, or becoming sticky or inelastic.

Additionally, insulating gloves must be given an air test during the required inspections. OSHA refers to ASTM F1236-96 (2012), “Standard Guide for Visual Inspection of Electrical Protective Rubber Products,” to identify methods and techniques for the visual inspection of electrical protective equipment made of rubber.

Electrical protective equipment must be stored appropriately to protect it from light, temperature extremes, excessive humidity, ozone, and other damaging substances and conditions.

Protector Gloves

OSHA requires protector gloves, with limited exceptions, to be worn over rubber insulating gloves to protect them from damage. Exceptions include the use of any insulating glove under limited-use conditions, such as when small equipment and parts manipulation necessitates unusually high finger dexterity. The employer must be able to demonstrate that the possibility of physical damage to the gloves is low, and the glove class must be one class higher than that required for the voltage involved. Additionally, OSHA allows limited exceptions for Class 00 and 0 gloves when high finger dexterity is required.

Insulating gloves that have been used without protector gloves cannot be reused until they have been tested and deemed safe to return to service.

Live-Line Tools

OSHA requirements for live-line tools are found in 1910.269(j) and 1926.957. A live-line tool is designed to contact an energized part and insulate the worker from that part. Typical tools include straight and shotgun sticks, telescopic sticks, disconnect sticks and link sticks. OSHA refers to IEEE 516-2009, “IEEE Guide for Maintenance Methods on Energized Power Lines,” for guidelines for the examination, cleaning, repairing and in-service testing of live-line tools. (Note: An updated version of the standard – IEEE 516-2021 – is now available.)

Condition of Tools

Tools are required to be wiped clean and visually inspected prior to use each day. If any defect or contamination is found that could adversely affect the insulating qualities or mechanical integrity of the tool, it must be removed from service, examined and then tested before being returned to service. Additionally, live-line tools used for primary employee protection are required to be removed from service every two years for examination, cleaning, repair and testing.

Testing

Testing must verify the tool’s integrity along its entire working length and, if the tool is made of fiberglass-reinforced plastic, its integrity under wet conditions.

The voltage applied during the testing includes 75,000 volts per foot of length for one minute if the tool is made of fiberglass; 50,000 volts per foot of length for one minute if the tool is made of wood; or other tests that the employer can demonstrate are equivalent. Although wood is still included in the standard, wood sticks are not typically used these days. Tests other than those specified by OSHA may include using hand-held, battery-powered hot-stick testers when they are used according to the manufacturer’s instructions and as OSHA requires in 1910.269(j)(2)(iii)(E)(3), which reads, “Other tests that the employer can demonstrate are equivalent” (italicized emphasis added).

Summary

Electrical protective equipment and live-line tools are considered insulating equipment, so they must be appropriately used and cared for to maintain their insulating capabilities. These OSHA standards highlight the importance of inspections and testing, which are critical parts of a PPE program. Lastly, it is important to read and use the applicable consensus standards to better understand effective methods of inspecting, maintaining, testing, and using electrical protective equipment and live-line tools.

About the Authors: Pam Tompkins, CUSP, CSP, is president and CEO of SET Solutions LLC. She is a 40-year veteran of the electric utility industry, a founding member of the Utility Safety & Ops Leadership Network and past chair of the USOLN executive board. Tompkins worked in the utility industry for over 20 years and has provided electric power safety consulting for the last 20-plus years. An OSHA-authorized instructor, she has supported utilities, contractors and other organizations operating electric power systems in designing and maintaining safety improvement methods and strategies for organizational excellence.

Matt Edmonds, CUSP, CIT, CHST, is vice president of SET Solutions LLC. A published author with over 15 years of safety management experience, he also is an OSHA-authorized instructor for general industry and construction standards. Edmonds provides specialty safety management services for electric power organizations throughout the U.S. He has been instrumental in the development of training courses designed for electric power organizations, including OSHA 10- and 30-hour courses and SET Solutions’ popular OSHA Electric Power Standards Simplified series.

About OSHA Electric Power Standards – Simplified: Topics in this series are derived from SET Solutions’ popular OSHA electric power course offered through the Incident Prevention Institute (https://ip-institute.com). The course is designed to help learners identify standard requirements and to offer practical ways to apply the standards.